In a conversation with EFY’s Nitisha, Minushri Madhumita, Co-Founder of ThinkRaw India, discusses the company’s solar initiatives aimed at revolutionising the agricultural sector.

Q. Can you tell us more about ThinkRaw and its range of products?

A. Founded in 2016 and based in Delhi, ThinkRaw India Private Limited started with a focus on solar power installations. We have since expanded to over 200 installations, primarily for industrial use, generating up to 500 kilowatts. Our innovative approach integrates IT and solar technologies, resulting in products like Dhivara Mitra, which addresses aquaculture challenges by managing dissolved oxygen and pH levels using IoT and RO systems powered by solar energy. We have also developed Krishi Dhanu, a solar-powered, IoT-enabled portable device for dispensing solid fertilisers in agriculture.

Q. Can you provide more details about these products?

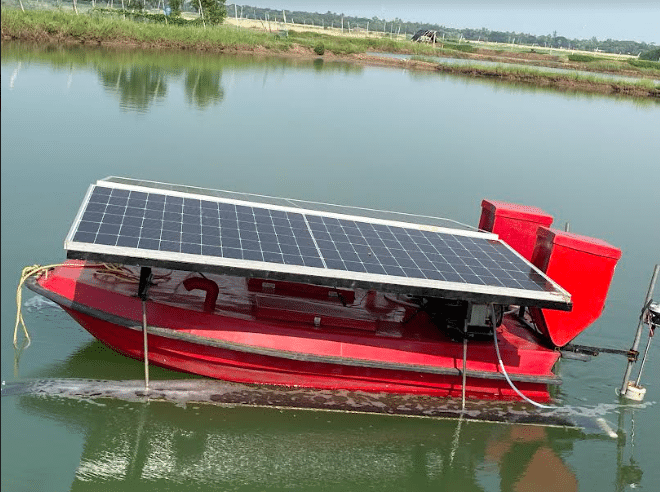

A. Our products cater to the aquaculture and agriculture sectors, offering efficient solutions for farmers. Dhivara Mitra, a floating vessel equipped with a 1.1-kilowatt solar-powered grid, provides comprehensive functionalities for aquaculture, including feed distribution, pH regulation, and oxygenation, ensuring optimal conditions for fish and prawn farming. It is equipped with IoT sensors that offer real-time monitoring and alert farmers to any imbalances. The vessel features a patented design made of glass fibre and incorporates solar panels for sustainable operation.

In agriculture, we offer Krishi Dhanu, a solar-powered portable device designed for dispensing solid fertilisers. Unlike traditional methods, which involve manual spreading or spraying, Krishi Dhanu simplifies the process by directly dispensing solid fertilisers. It uses two motors for grinding and dispersing the fertiliser, with a moderator to control the application rate. The device is complemented by an IoT-enabled wind machine, which records and stores data on fertiliser usage and types. Additionally, it integrates with crop and soil monitoring applications, enhancing decision-making for farmers by providing insights into fertiliser requirements and soil conditions.

Q. Do you have patents for these products?

A. Yes, we have filed for three patents for Dhivara Mitra, covering its DC motor, design, and feeding system, with two already granted. Additionally, we have applied for a patent for Krishi Dhanu, which is expected to be approved within the next one to two months.

Q. How does Dhivara Mitra function, and what sets it apart?

A. Dhivara Mitra uses solar panels to absorb sunlight and convert it into electricity in the form of DC. Unlike typical household setups where an inverter converts DC to AC power, our system uses DC motors that run directly on solar energy, eliminating the need for an inverter. During daylight hours, the solar panels generate electricity, some of which charges a solar battery for use in the evening when sunlight is unavailable. This off-grid setup provides a four-hour battery backup for evening operations. For prawn farming, where clients require an extended backup of up to eight hours, we offer an optional one-kilowatt upgrade solution, similar to an EV charging station. This solution is easily installed on the water body’s bank, allowing for plug-and-play functionality.

Q. What are the plans for the charging station setup?

A. The establishment of the charging station is the next phase of our project. Currently, the machine comes with a four-hour battery backup.

Q. Do you produce everything in-house?

We source the vessel from MECHEM, a renowned shipbuilding company in India. While we customise motors from the market, we manufacture the vessel’s structure and internal components, including sensors, solar panels, and other IoT applications, entirely in-house through our R&D efforts. However, we rely on the market for hardware devices.

Q. Do you procure components domestically or internationally?

A. Everything is manufactured in India except for the sensors. Despite our efforts to utilise domestically made sensors, we encountered reliability issues during testing with six different types. The readings were inaccurate, and the longevity was insufficient, posing a challenge, especially for farmers who cannot afford frequent replacements. Thus, we prioritise sourcing reliable sensors and products. Presently, the most effective ones we employ are imported from Germany.

Q. What unique features does Krishi Dhanu offer?

A. Krishi Dhanu includes an integrated application designed specifically for its purpose. It features an IoT-enabled weighing machine with sensors placed within a stand on agricultural land. This setup allows users to monitor NPK (nitrogen, phosphorus, and potassium) and moisture levels directly from the soil after fertilising, even when the machine is back home. It offers a comprehensive solution comprising both hardware and software applications.

Q. What is included in the Krishi Dhanu product?

A. When purchasing this application, the client receives two distinct components: the software application and the hardware. The hardware dispenses the required amount of fertiliser and includes quality sensors. Additionally, a stand with sensors is provided for insertion into the soil. The Android application must be installed on users’ mobile devices. This solution is customisable; for those who prefer not to use applications, sensors alone can be provided, while others can opt for both sensors and applications. It is a comprehensive solution tailored to individual preferences. The entire device costs Rs. 39,000 as a one-time payment, while the application operates on a subscription model.

Q. Can ordinary boats customised into solar ones?

A. The boats are used for fish and prawn farming, distinct from passenger boats. Customisation options are available; for instance, we can convert a boat into a solar powered one. However, certain constraints exist. Unlike conventional ones, glass fibre construction is necessary for such ships. Moreover, substantial battery capacity is required. Approximately 70% of our efforts focus on achieving buoyancy and efficient movement for a boat carrying a 180 kg load on water. This challenging task necessitates remote control or full automation for optimal functionality.

Q. Is it fully automated?

A. We have not achieved full automation yet, so the application needs the user’s geolocation to implement it. If the user has multiple ponds, each one requires a separate geolocation. However, we understand this limitation and have expertise in GIS and GPS to address it. While we have not achieved full automation yet, we can meet the demands of farmers who prefer a completely hands-off approach.

Q. What are the prices for these devices?

A. For boats, there are two pricing tiers: one at 5.5 lakh per unit and the other at 6.6 lakh per unit. The former one is for farmers with one-acre land who can manually measure digital oxygen level and pH level of the water body. Some farmers opt not to spend the extra one lakh due to the high cost of sensors. The price is 5.5 lakhs without sensors, and the machine operates without the Android application. With sensors, the cost rises to 6.6 lakhs. While these are expensive units, significant subsidies are available. The Government of Odisha offers 40 to 50% subsidies through the Fishery Department, and the National Fishery Development Board provides a 30% subsidy. Additionally, as these products are solar-powered, farmers can avail of a 30% subsidy from the Ministry of New and Renewable Energy.

Q. What is the lifespan of these products?

A. Dhivara Mitra includes a glass fibre vessel with a lifetime warranty. The solar panels typically last 20 to 25 years, while the solar-charged batteries last five to seven years. Motors have a standard one-year warranty that lasts six to seven years. Annual maintenance charges mirror those of Krishi Dhanu. Similarly, sensors and batteries adhere to industry norms. The vessel, also made of glass fibre, is covered by a lifetime warranty.

Q. How many units have been sold?

A. Fifteen units of Krishi Dhanu have been sold, with ten designated for the Farmer Federation aided by the Odisha Livelihoods Mission and the remaining five allocated to the SELCO Foundation. Additionally, five units of Dhivara Mitra have been sold.

Q. What impacts does rain have on solar panel efficiency?

A. We have implemented dual-sided panels, integrating the latest technologies into our product. Today, solar technology isn’t solely reliant on sunlight; photons, the energy creators, are essential. Even during heavy rainfall, when clouds obstruct direct sunlight, there is still energy generation potential. Additionally, rainfall enhances natural aeration due to increased water movement. Cloudy weather without rain may pose challenges, but rain ensures sufficient water movement for optimal performance.

Q. What options are available for financially constrained farmers to access these products?

A. If someone cannot afford to buy it outright, they can rent it. As mentioned earlier, five units have been sold through NABARD to a farmer-producer company, and one unit has been rented out to a farmer at a monthly rate of 10,000 rupees. Additionally, there is a customer hiring centre for fertiliser machines, although it is yet to be established. The ten units sold to the Orissa Livelihoods Mission-supported Farmer Federations are rented out to various farmer producer organisations (FPOs). Here is how it works: let us consider a self-help group with 14 members. One group member is trained to operate the machine, and they collectively cover the labour charges and machine rental, amounting to around 1000 rupees per day. This setup allows them to manage agricultural tasks in the face of labour shortages efficiently.

Q. What is your preferred distribution strategy?

A. We have two potential approaches to conducting our business. Firstly, we can directly engage with large-scale farmers who purchase bulk quantities, such as those procuring 500 or 1000 units. These farmers can serve as our direct channel partners, enabling us to sell to them directly. Secondly, we aim to collaborate with Farmer Producer Organisations (FPOs). FPOs typically consist of 300 to 2000 members, providing us with an access to a substantial customer base in one go. By establishing distributorship channels with FPOs, we can sell through them. They will leverage their dedicated member lists to pitch our products and receive a 10% commission on sales.

Q. What about FPOs and dealerships?

A. Five units were initially sold directly, but moving forward, the same FPOs that would have conducted these sales will serve as our distributorship channel. This process is underway, with FPOs already generating a pipeline for us. Additionally, working upon building some dealership network with vendors specialise in equipment used in the aquaculture sector. Since they have an established customer base and expertise in aquaculture, it makes sense to include them in our business model. These dealers will develop sales channels for our product, receiving a 10% commission on sales they generate. This margin of 10% is reserved for both dealers and distributors.

Q. Where is your current manufacturing facility located, and what are your plans for expanding production?

A. Our small assembling unit in Paradeep, Orissa, is holding us back, but we are trying to get funds to expand by building a giant plant. We have applied for land and hope to get it in the next few months. Orissa is a good place because we are both from there, and the government greatly supports startups. They are even giving us big discounts on land. Our product branding is already good, and government policies are helping us, too. We will start with Orissa.

Q. What are your revenue sources?

A. We generate revenue by establishing solar setups, selling the market-ready versions of our product innovations and offering rental services for market-ready versions of our products on them.

Q. What obstacles do businesses in this sector typically face?

A. The initial challenge often revolves around people’s resistance to change. Despite the numerous accomplishments of women in technology, there remains a lingering doubt regarding their leadership decisions and technical abilities. This scepticism persists, making it challenging to shift mindsets, especially among farmers. As a tech company involved in social development initiatives, a key aspect of our work consists in raising awareness and demonstrating the benefits of our products to farmers. Convincing farmers to invest in our solutions is challenging due to prevailing attitudes that regard farming as a low-status profession. Despite the affordability of our products for many farmers, the main obstacle lies in changing societal views on farming and acknowledging the progressive nature of farmers.

Q. What are your future expansion plans?

A. We are expanding globally, with plans to establish a presence in Canada within the next few months. Canada’s extensive freshwater and saltwater resources, which comprise the longest chain in the world, present a lucrative opportunity for our business. Additionally, with 30% of Canada’s economy stemming from fish and prawn farms, we see tremendous potential in this market. Furthermore, we are eyeing opportunities in other American countries and Asian nations like Indonesia and Bangladesh. Our goal is to become a truly global company.

Q. How has your business grown recently, and what is next?

A. We currently employ 11 individuals solely dedicated to solar projects. Our R&D team is separate from this group. While we don’t include our partner’s employees in our headcount, they work around the clock on our projects. This collaborative effort has fuelled our growth, both financially and in terms of reputation. Our revenue, team size, and brand recognition have all more than doubled from 2016 to 2023. Despite starting with minimal investment, we have exceeded expectations, with revenues now surpassing two crores.