Solar photovoltaic panels produce energy only while the Sun shines, but lighting is required mainly during the night. So, solar energy must be stored, which is generally done through lithium-ion batteries.

Solar photovoltaic panels produce energy only while the Sun shines, but lighting is required mainly during the night. So, solar energy must be stored, which is generally done through lithium-ion batteries.

But lithium-ion batteries have some limitations…

First, the cost of lithium-ion batteries is increasing year after year, so these are suitable for high-priced mobile items like vehicles and smartphones only. For stationary applications, we need to find alternatives.

Second, lithium-ion batteries can handle a few thousand charge/discharge cycles only. This means the batteries need to be replaced after about five years of use.

Third, recycling lithium-ion batteries is challenging and expensive. Also, India does not have lithium mines, so we are completely dependent on imports.

Fourth, lithium-ion batteries also use metals like nickel and cobalt. Therefore, these batteries are not environment-friendly. Besides, a lot of mining is required to get these metals.

Also Read: Different Types of Batteries

Hence, it becomes important to explore other devices for energy storage. Here we will explore the use of supercapacitors for energy storage for low-power but widespread applications.

Supercapacitor Benefits

Supercapacitors (or ultra-capacitors) are also called electric double-layer capacitors. They use porous carbon electrodes and store energy in the form of an electric field. Unlike batteries, which store energy in electrochemical form, these offer high-value capacitance, which can be measured in Farads. The typical working voltage of these capacitors is low (2.7V).

Supercapacitor Weakness

As of today, the cost of supercapacitors is high. Just for storing a few watt-hours of energy, we have to use several capacitors. Hence, the cost of even small low-power systems is fairly high.

Cost Reduction Tips

However, there are some ways the cost of supercapacitors can be reduced, a couple of which are suggested below.

Mass Production:

As discussed earlier, supercapacitors do not need expensive raw materials. So, their high cost is mainly due to their low volumes of production. Therefore, there is a need to identify applications that can generate a big demand for them. As their demand and production up, automatically the manufacturing cost will come down.

Redesign for Slow Charge/Discharge Applications:

Most supercapacitors available in the market are designed for handling high (in amps) charge/discharge currents. Therefore, these supercapacitors have thick terminals and large electrodes. However, in small solar applications, the capacitor charge/discharge currents are low (in milliamps). Hence, for such applications capacitor design needs to be optimized to reduce cost and size.

The supercapacitor-based clock is one of the best-suited applications. Clocks use low-power AA primary batteries, which need to be replaced almost every year. Every house has a few such clocks. So, we consume a large number of batteries every year, which contain hazardous chemicals. These batteries are not properly disposed of, so they pose a big threat to the environment and health.

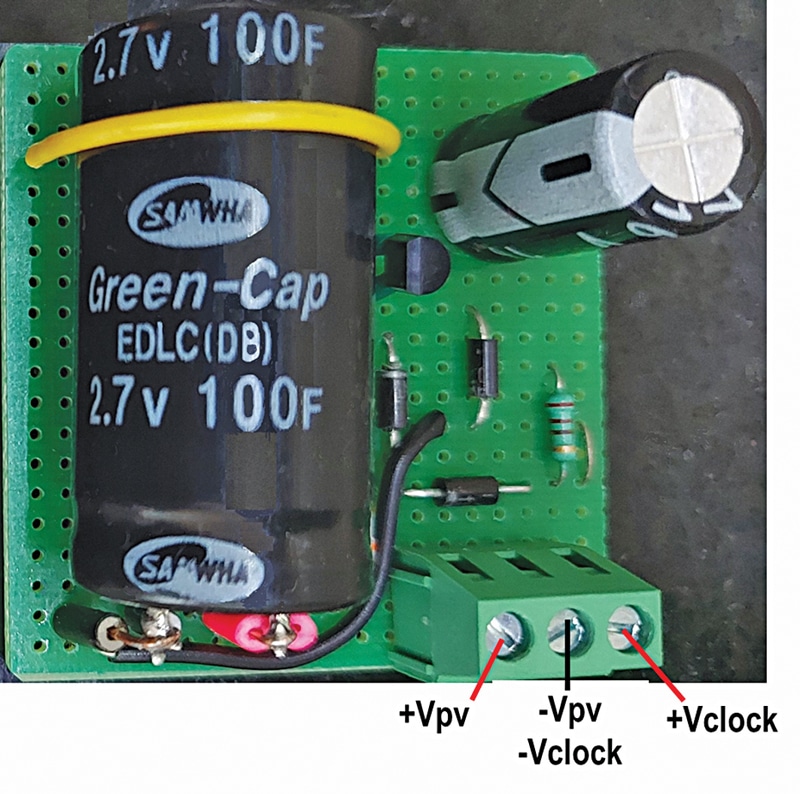

The author’s prototype of a clock power supply using solar PV and a supercapacitor is shown in Fig. 1. The aim is to run the clock nonstop for at least 15 years under all weather conditions. This will eliminate the use of about 15 AA cells for each clock and reduce hazardous chemical waste.

Circuit Diagram

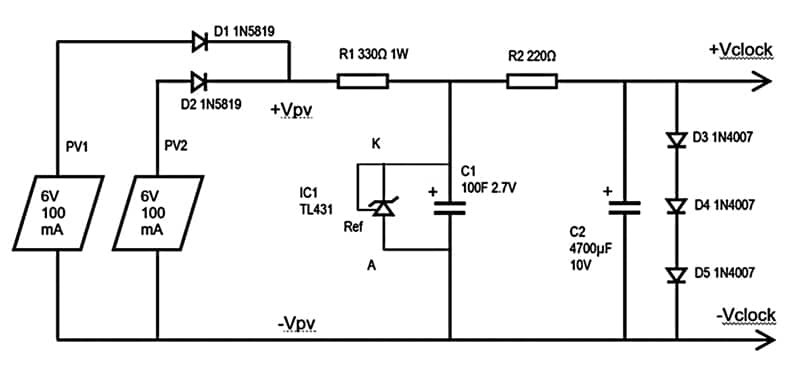

Fig. 2 shows a circuit diagram of the proposed power supply. The circuit uses two small 6V/100mA (PV1 and PV2) solar panels, two 1N5819 Schottky diodes (D1 and D2), three 1N4007 rectifier diodes (D3, D4, and D5), shunt regulator ICTL431 (IC1), 100F/2.7V supercapacitor (C1), 4700µF/10V electrolytic capacitor (C2), and a few other components.

The following are the specifications of the solar panels:

Voltage at maximum power=Vmp=5V (depends on sunlight intensity)

Current at maximum power=Imp=100mA

Open circuit voltage= Voc=6V

Size=70mm×70mm

These panels are connected in parallel using Schottky diodes D1 and D2. The diodes block the current from one panel entering the other panel.

The panel output voltage Vpv is fed to supercapacitor C1 through current-limiting resistor R1. Voltage regulator IC1 is connected across C1 to regulate the capacitor’s voltage to 2.5V.

IC1 ensures that the capacitor voltage never exceeds the rated voltage of 2.7V. Note that, diodes D1 and D2 also stop C1 from discharging into the panels when there is no sunlight.

The output of capacitor C1 is connected to the clock terminals through the current-limiting resistor R2. Across these terminals diodes D2, D3, and D4 are connected in series.

Total forward voltage of D2, D3, D4=0.65V×3=1.95V

The clock movement operates in the range of 2V to 1V. Thus, the three diodes limit the voltage Vclock to less than 2V. Capacitor C2 is used to reduce voltage dip whenever the movement draws pulse current.

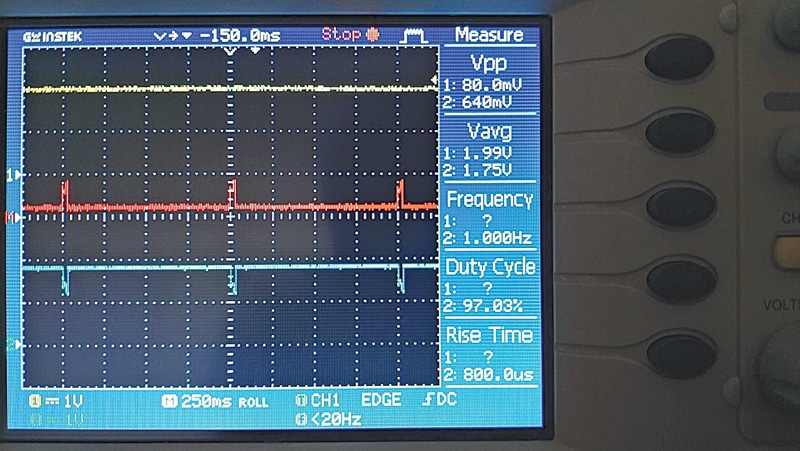

The working of the project will be clearer from various waveforms shown in Fig. 3 through Fig. 5.

Fig. 3 shows the C1 capacitor voltage and +Vclock voltage. These waveforms were captured without mounting the filter capacitor C2. Also, the value of resistor R2 was changed to 100Ω.

As seen in Fig. 3, the capacitor voltage is stable at 1.99V. We see a dip in +Vclock voltage every second when the clock movement draws pulse current.

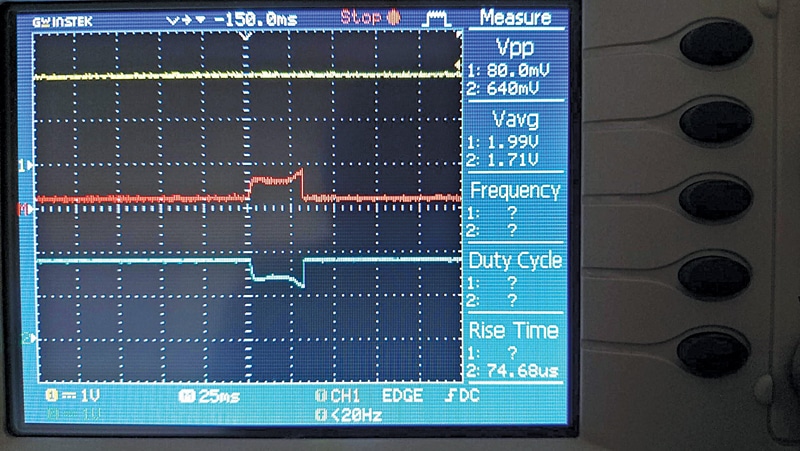

Using the math function of the oscilloscope, trace M (red) has been plotted, which gives the difference between Ch1 and Ch2. This waveform is the voltage across resistor R2. Fig. 4 shows the same waveform expanded.

From the red trace of Fig. 4, we can calculate the current through R2.

Please register to view this article or log in below. Tip: Please subscribe to EFY Prime to read the Prime articles.

Thanks for the design of Low Power Standby or Backup Battery using Super Capacitor and Solar Panel. Is this economical enough? As a Super Capacitor costs from Rs.200 up to Rs.7500 and Solar Panel costs from Rs.100 up to Rs.3500, is this the right alternative for Li Ion or Alkaline Batteries? Or, are there suitable means to increase the overall storage capacity so that they can replace conventional Primary or Secondary Batteries? Although a Super Capacitor holds charge in the range of tens of Farads, their delivery of power over a long period is still below the actual field requirements.

Thanks again.

Dear Chithraa,

“This is a good observation.

Demand for energy storage devices is increasing exponentially. Following are broad guidelines through which we can try to meet the demand.

1) Explore all types of storage devices.

2) Try to take advantage of their unique features. For example, supercapacitors can be charged and discharged 100000 times. So, it has 3 times more life than a lithium-ion battery even after charging several time in a day. Also, supercapacitors are environment friendly.

3) The cost issue can be tackled by increasing production. For that, we have to identify applications which are low lying fruits. This way, we can generate initial demand which will result in reduced price. In turn it will open up newer applications and improved capacitors.

With above points in mind, the clock power supply circuit has been designed. Even though it is a very small power application, it has the potential to eliminate crores of AA batteries. Thereby reducing hazardous waste.

Lastly, use of lithium-ion batteries for stationary applications is a waste of precious resource.

As far as solar panels are concerned, they have a long life of >25 years. Problem is the initial cost. That is the reason the government is offering subsidies. ”

Regards